Technologies

3D printing

Technologies

EBBAMS is a state-of-the-art factory equipped with a wide variety of 3D printers. We utilize revolutionary additive manufacturing technologies to provide superior solutions, lower risks, less cost, and less manufacturing time.

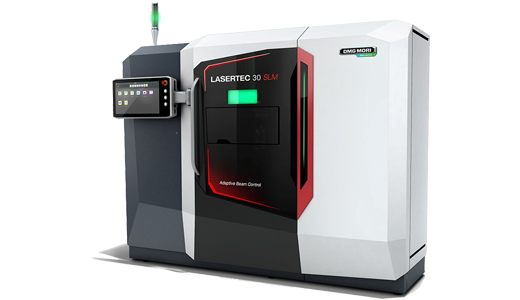

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a cutting-edge 3D printing technology that uses a high-powered laser to fully melt and fuse metal powder layer by layer, creating complex, high-strength parts with exceptional precision. Ideal for aerospace, medical, and industrial applications, SLM enables the production of lightweight, durable, and geometrically intricate components that are impossible to achieve with traditional manufacturing.

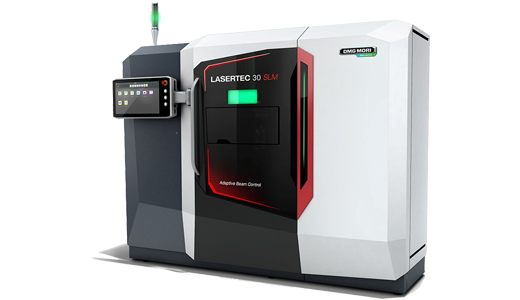

Selective Laser Melting (SLM)

Selective Laser Melting (SLM) is a cutting-edge 3D printing technology that uses a high-powered laser to fully melt and fuse metal powder layer by layer, creating complex, high-strength parts with exceptional precision. Ideal for aerospace, medical, and industrial applications, SLM enables the production of lightweight, durable, and geometrically intricate components that are impossible to achieve with traditional manufacturing.

Stereolithography (SLA) Formlabs

Stereolithography (SLA) by Formlabs delivers unmatched precision and surface quality, using a powerful laser to cure liquid resin into solid layers with exceptional detail. This technology is perfect for creating prototypes, dental models, jewelry, and engineering parts with smooth finishes and intricate geometries. With a wide range of advanced resins, Formlabs SLA combines reliability, speed, and versatility—making it a trusted choice for professionals across industries.

Stereolithography (SLA) Formlabs

Stereolithography (SLA) by Formlabs delivers unmatched precision and surface quality, using a powerful laser to cure liquid resin into solid layers with exceptional detail. This technology is perfect for creating prototypes, dental models, jewelry, and engineering parts with smooth finishes and intricate geometries. With a wide range of advanced resins, Formlabs SLA combines reliability, speed, and versatility—making it a trusted choice for professionals across industries.

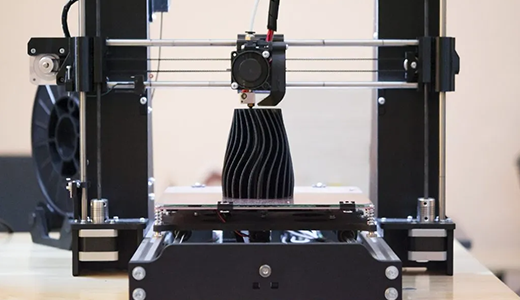

Fused Deposition Modelling (FDM)

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, known for its simplicity, reliability, and cost-effectiveness. It works by extruding heated thermoplastic filament layer by layer, creating durable parts with strong mechanical properties. Ideal for rapid prototyping, functional testing, and even end-use production, FDM offers a wide choice of materials and colors, making it a versatile solution for industries ranging from education and design to engineering and manufacturing.

Fused Deposition Modelling (FDM)

Fused Deposition Modeling (FDM) is one of the most widely used 3D printing technologies, known for its simplicity, reliability, and cost-effectiveness. It works by extruding heated thermoplastic filament layer by layer, creating durable parts with strong mechanical properties. Ideal for rapid prototyping, functional testing, and even end-use production, FDM offers a wide choice of materials and colors, making it a versatile solution for industries ranging from education and design to engineering and manufacturing.